SERVICES

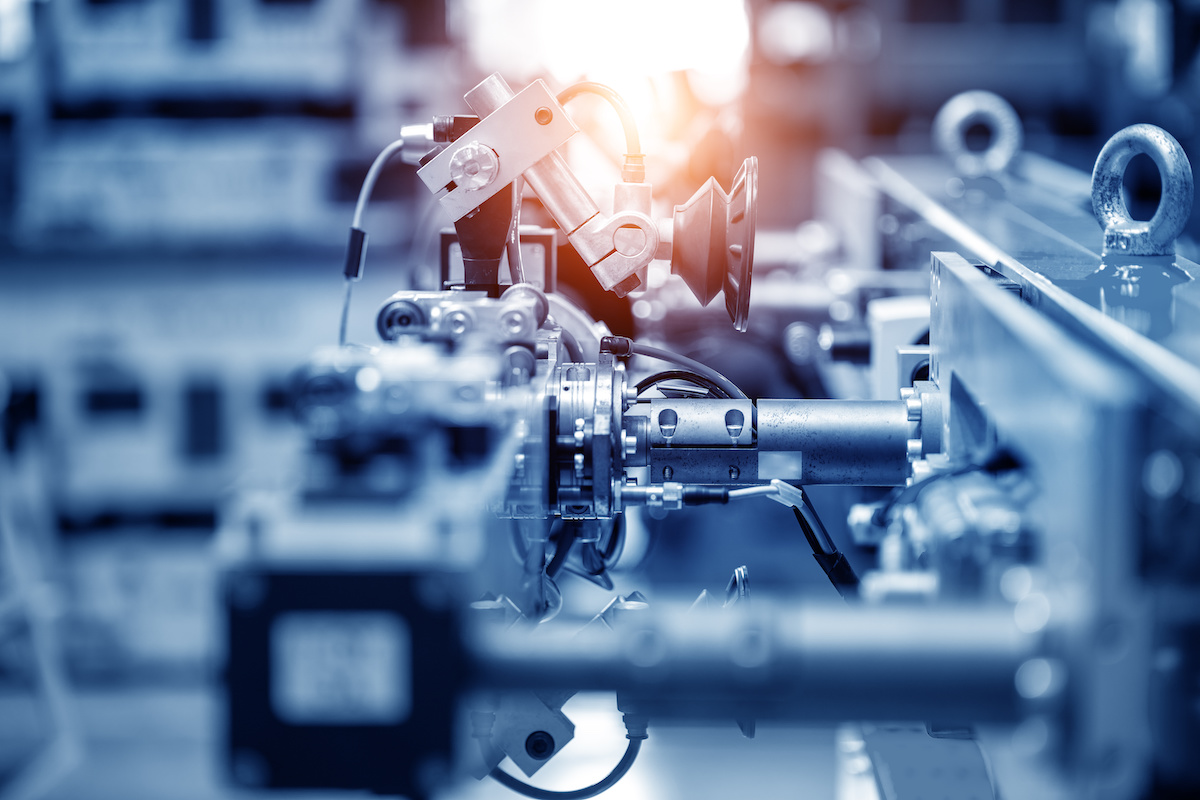

Equipment Launch Support

Manufacturing equipment launch consulting support helps companies integrate new equipment by providing expertise in project management, process optimization, and staff training to ensure a smooth and efficient transition, which maximizes return on investment and minimizes downtime. i2e consultants assist with everything from pre-launch planning and vendor management to post-launch monitoring and optimization.

Key aspects of manufacturing equipment launch consulting support

- Project and Program Management: Consultants manage the entire launch process, including coordinating with contractors, managing documentation, and handling program close-out.

- Process and Operational Optimization: They analyze current operations and use qualified methodologies to improve production processes, enhance quality control systems, and reduce waste.

- Technology and Systems Integration: Consultants help integrate new equipment with existing systems, which can include modernizing legacy machinery with technologies like IoT and cloud platforms to enable real-time data insights and predictive maintenance.

- Staff Training and Development: Experts train employees on how to operate the new equipment correctly, ensuring the team can use the systems effectively to maintain quality and productivity.

- Quality and Maintenance Support: They help implement robust quality control systems and develop predictive maintenance strategies to anticipate and prevent issues before they cause downtime.

- Vendor and Contractor Coordination: Consultants coordinate with vendors, manage spare parts lists, and ensure all necessary documentation, such as as-installed drawings, is properly coordinated.